Register

Login

- Home

Quota

Pay

- Company Info

- Product Info

- About Us

- Blog

- Privacy

-

Email:info@pandapcb.com

-

OnLine Server

wx chat

wx chat

| Project | Processing Capability | Process Explanation | Illustrations/Notes |

|---|---|---|---|

| Number of layers | Floors 1-100 | The number of layers refers to the number of electrical layers (copper layers) in a PCB. Nissan Electronics accepts quotes for high, medium, and low difficulty boards in military, automotive, mobile, aviation, LED, and other industries | |

| Board type | FR-4 and other special boards | Board type: supports special board production, ordinary all glass fiber (FR-4) six glass cloth/four glass cloth, as shown in the right figure |  |

| Adopting production processes | Universal FR-4, along with other special processes | Traditional tin plating process positive film | |

| Maximum size | Universal 122cm * 55cm | Both sides cannot be larger than 55cm at the same time (one side can be made 122.9cm, the other side must be smaller than 55cm), and customization is supported | |

| Resistance welding type | Universal photosensitive ink, supports other inks | Universal photosensitive ink is currently the most commonly used type, while thermosetting oil is generally used in low-grade single-sided cardboard. As shown in the figure on the right |  |

| Finished product outer layer copper thickness | Universal 1oz, supports thick copper plates | The default thickness of the outer copper foil circuit of the conventional circuit board is 1oz | |

| Accuracy of external dimensions | Universal ± 0.15mm, supporting envoy requirements | Universal board shape tolerance ± 0.15mm | |

| Plate thickness range | 0.8-1.6mm | Nissan's current production plate thickness is 0.8/1.0/1.2/1.6 | |

| Plate thickness tolerance (T ≥ 1.0mm) | ± 10% | For example, if the thickness of the board is T=1.6mm, the actual board thickness is 1.44mm (T-1.6 × 10%)~1.76mm (T+1.6 × 10%) to 1.76mm (T+1.6 × 10%) | |

| Plate thickness tolerance (T<1.0mm) | ±0.1mm | 0.7mm(T-0.1)~0.9mm(T+0.1 | |

| Bore diameter (mechanical drilling) | Universal 0.2-6.3mm | Support special requirements, with a minimum aperture of 0.2mm and a maximum aperture of 6.3mm. If the aperture is greater than 6.3mm, the factory will need to handle it separately. The specification of the mechanical drill bit is 0.05mm, which is first order, such as 0.25mm and 0.3mm | |

| Aperture tolerance (machine drilling) | Universal ± 0.075mm | Special requirements are supported, with a tolerance of ± 0.075mm for drilling. For example, for a hole designed to be 0.6mm, the finished hole diameter of the physical board is qualified and allowed to be between 0.525-0.675mm. | |

| Line width | Universal 3.5mil, supports special requirements | Single double-sided board and multi-layer board are both 3.5mil | |

| Line gap | Universal 4mil, supports special customization | Both single-sided and multi-layer boards are 4mil | |

| Minimum through-hole inner diameter | Support special customization, with a minimum of 0.2mm for universal and outer diameter inner diameter (hole) and 0.45mm for outer diameter (diameter) | Support special customization, with a minimum inner diameter of 0.2mm and a minimum outer diameter of 0.45mm for universal multi-layer boards, and a minimum inner diameter of 0.2mm and a minimum outer diameter of 0.45mm for double panels | |

| Distance from pad edge to line | Universal 8mil | Support special customization, parameter is the limit value, try to exceed this parameter as much as possible | |

| Through hole unilateral welding ring | Universal 5mil, supports special customization | The universal board parameter is the limit value, try to exceed this parameter as much as possible | |

| Minimum character width | Support special customization, universal line width 4mil, character height 27.5mil | The general parameter is the limit value and should be as large as possible |  |

| Single piece shipment: distance between wire routing and pad edge | Universal ≥ 0.2mm, supports special customization | Support special customization, universal board, otherwise it may involve circuits and solder pads inside the board |  |

| Splitting V for shipment: distance between wiring and solder pads to the edge of the board | Support special customization, universal ≥ 0.4mm | Universal boards may involve circuits and solder pads inside the board. If it is a patchwork, the distance between the lines and the edges must be 0.4mm, otherwise V-cutting may damage the circuits. If it is a single piece shipment, a spacing of ≥ 0.2mm needs to be provided. |  |

| Minimum process edge | Universal 3mm, supports special requirements |  |

|

| V-CUT |

Minimum distance from V-CUT to line V-CUT offset V-CUT excess thickness V-CUT angle V-CUT upper and lower blade overlap V-CUT upper and lower blade depth deviation |

According to customer requirements, if there is no customer requirement, the plate thickness should be 1/3 according to customer requirements. If there is no customer requirement, a 30 ° knife should be used | ≥0.5mm ±0.15mm ±10% 25-30° ±0.05mm ±0.1mm |

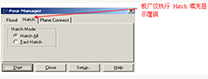

| Note 1: Pads manufacturer's copper laying method | Hatch copper laying method, supporting special methods | The manufacturer uses Hatch copper reduction and PADS software design. Customers must pay attention to this. As shown in the figure on the right |  |

| Note 2: Drawing slots in Pads software | Using the Outline line, supporting the envoy approach | If there are many non-metallic grooves on the board, please use outline to draw |